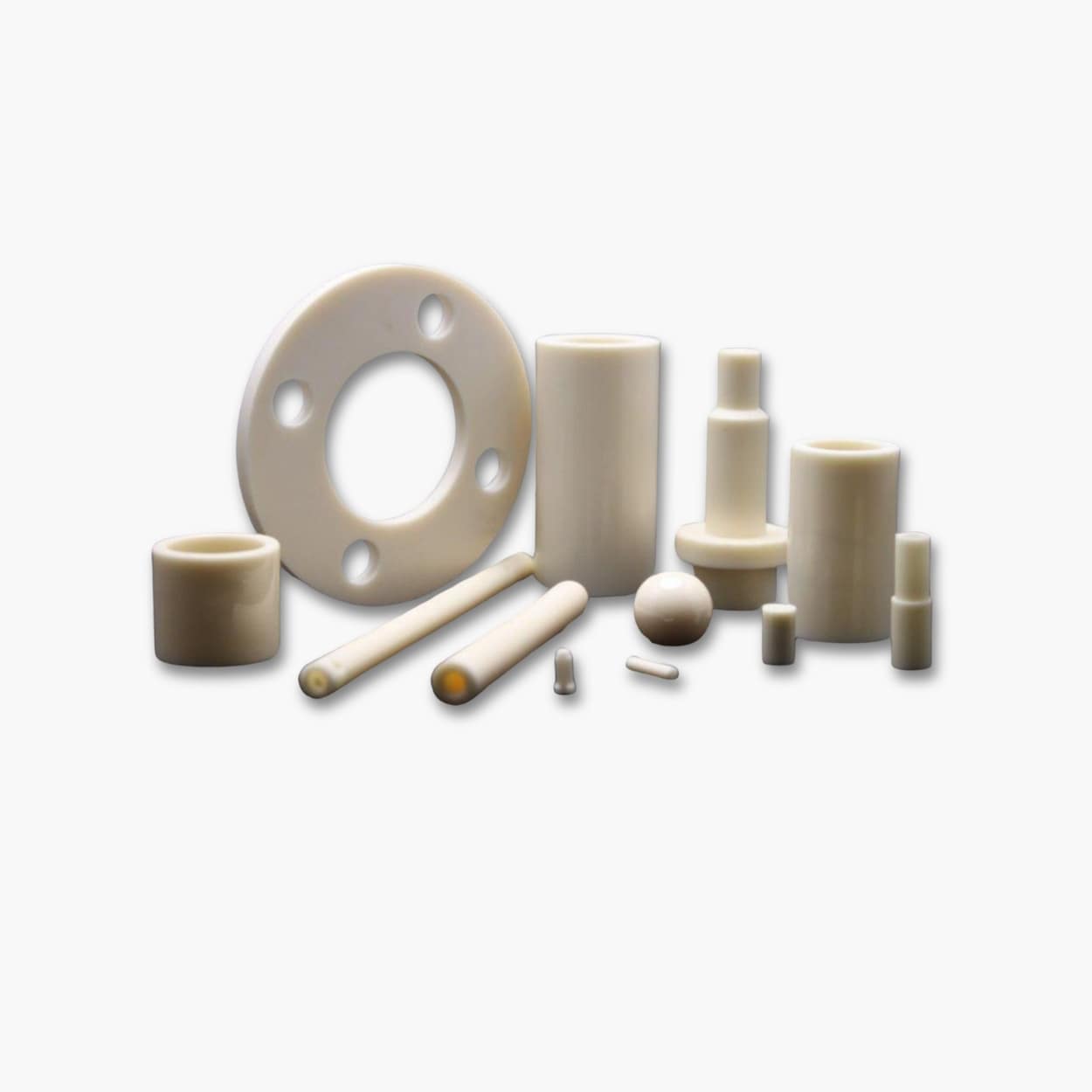

PTFE Customised Parts

Because of its unique molecular structure, granular PTFE does not melt and cannot be molded into complex forms like other plastics. However, it can be easily machined on all standard equipment, including advanced CNC machining equipment. PTFE can be cut, bored, milled, and turned using standard tooling. Normally, PTFE is machined to tolerances of about plus or minus 0.005 inches. While closer tolerances are occasionally required, they are usually not necessary. PTFE is very resilient, which allows machined parts to conform to most working dimensions. A part can sometimes be press-fitted at a lower cost than performing final machining to exact size. When closer tolerances are required, it is essential to use stress-relieved products. Fluoro-Plastics offers complete annealing services to industry standards for all stock shapes we manufacture. Tolerances of plus or minus 0.001 inches can be achieved with Fluoro-Plastics shapes that have been properly annealed at our factories. Fluoro-Plastics has a complete machine shop to produce finished parts from prototypes up to production quantities. We have been fabricating and machining PTFE for over 50 years. Call Fluoro-Plastics with any design questions or send us a drawing by fax or email and let our experience work for you. See ASTM D 3297 for machining specifications.

Electrical applications: PTFE is one of the best insulators known. In thin sections, it will insulate to 500 volts per mil. There are grades if PTFE which have even greater dielectric strength. It is frequently used in wire and cable wrap, and to separate conductive surfaces in capacitors. Thick walled close-tolerance extruded tubing is the PTFE shape of choice where machining or drilling long lengths to close tolerances is impossible. Multi-hole tubing can be extruded. PTFE can be machined into standoff insulators, and many different types of high voltage encapsulation devices for electrical components.

Availability : Tube, Bush, Collar Bush, Machined Parts, Mica on SS Rods.

TUBES :

ID : min 8 mm

OD : max 1400 mm